APA®2000

Primary Supported Industries: Healthcare

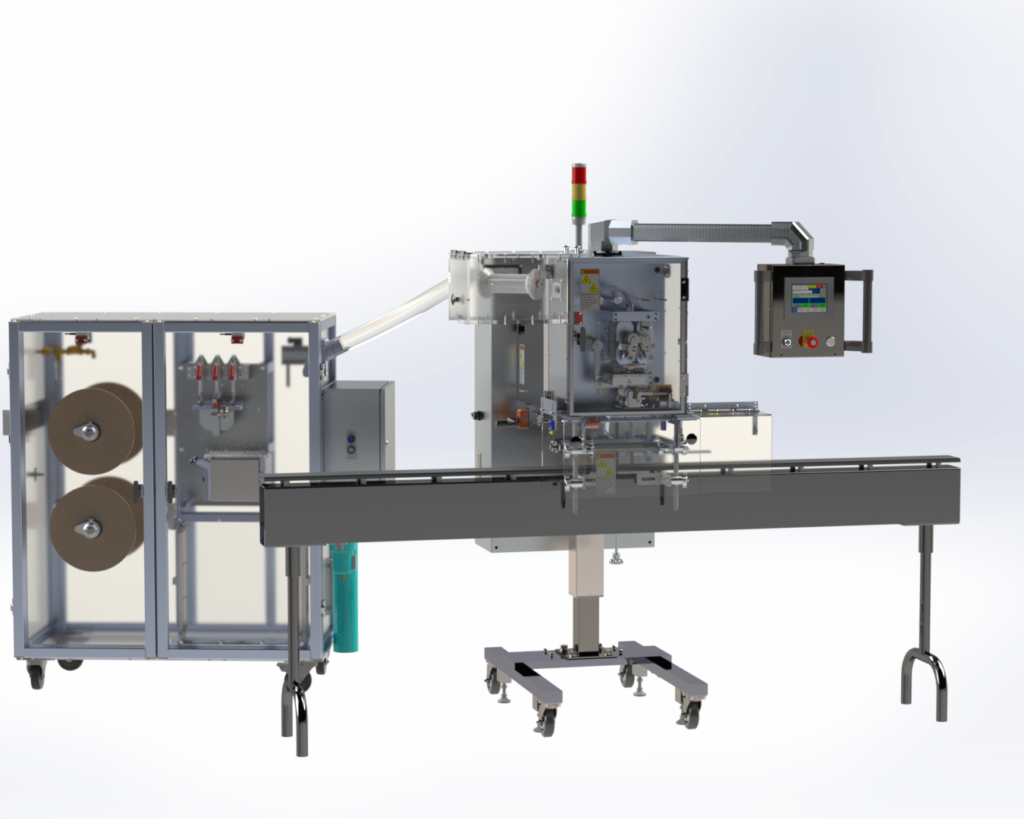

The Multisorb APA®2000 model is the dispenser component of the StripPax® and StabilOx® systems. Our systems approach combines the proven performance of our spooled sorbent packets with the industry recognized reliability of our APA®2000 sorbent packet dispenser. The APA®2000 is custom manufactured and works exclusively with StripPax® and StabilOx® packets.

The APA®2000 is designed for maximum performance while still emphasizing build quality and reliability. Designed with high speed components and controls, the APA®2000 can process spooled StripPax® and StabilOx® product up to 300ppm.

The APA®2000 dispenser is easily interfaced with existing or new bottling lines, and can also be a fit for device or tray placement, VFFS, HFFS, flow wrapping machinery, and can be modified for custom integrated applications.

APA®2000 Packet / Pouch Dispenser

Multisorb’s APA®2000 is a high-speed StripPax® and StabilOx® packet dispenser that can handle your production process up to 300ppm, depending on project details. Designed and built in the US to meet CE standards for pharmaceutical and nutraceutical use, the APA®1500 can be provided with a variety of interfaces, suitable for bottling lines, medical devices, tray/cavity placement, and many other unique applications.

APA®2000 Features

Performance

- Speeds up to 300ppm with bottle screw interface.

- Self-initializing product feed

- Servo-driven cutting mechanism

- Powered spool unwind in separate enclosure

- Pinch Roller device for accelerated product delivery

Controls

- PLC controlled for robust and reliable performance

- Color touchscreen HMI (Human-Machine Interface)

- Recipe based storage for instant parameter recall

- Packet length inspection & verification performed on every sachet

- Onboard diagnostics and performance trending

Reliability

- Enclosed system to protect product in-process

- Servo-driven anti-slip indexing belt drive for enhanced and precise product control

- Category III Safety Circuit with interlocked doors and guarding

- Multi-point sensor array to monitor product throughout processing

Integration

- Designed for integration over existing conveyor/equipment

- Mobile base with integrated self-leveling stabilizing feet

- Adjustable height jack stand with digital indicator

- Toolless rapid product changeover

Optional Features

- Dry Air Purge Kit to protect desiccants during extended breaks or line stops. Includes on-board air filter/dryer, flow controls, and dew point monitor wired and alarmed to PLC.

- Inert Gas Purge Kit to protect oxygen absorbers during extended breaks or line stops. Includes on-board flow controls and oxygen monitor wired and alarmed to PLC.